|

FEATURE |

| Steel Tech Dishwashers |

| |

| Ecology and economy |

|

| |

ProTect environment protection

Our dishwashers feature extremely low noise levels, four times

lower than previous models, and have been designed considering the

need to reduce electromagnetic emissions, water consumption and

carbon footprint.

The Colged plant is ISO 14001:2004 certified, thus confirming

the company’s attention to protecting the future of our planet. |

| |

|

| |

|

|

ProDuct quality concept

Colged machines are designed and constructed in compliance

with an ISO 9001:2008 certified quality system and incorporate the

unique experience of a manufacturer who, during its many years of

business, has sold more than one million industrial dishwashers. All

electric and electronic components are sourced in Europe and external

suppliers are subject to stringent controls.

|

| |

|

| Innovation and performance |

|

|

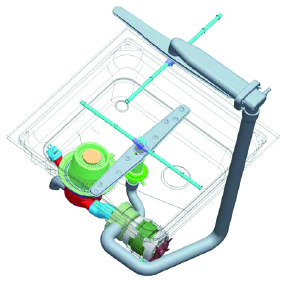

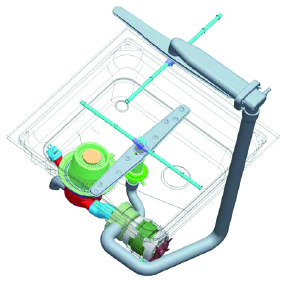

DuoFlo pump

A conventional pump has an inlet (from the tank) and an outlet

towards the two spray arms: the flow of water must be distributed

using a T or Y connector. Our research has revealed that this is where

25 - 30% of power is lost. Colged has eliminated the problem with a

simple solution: the pump has one inlet but two outlets without any T

divider. Loss is not only reduced but completely eliminated, with also

a 50% reduction in noise. A 480W DuoFlo pump delivers the same

performance as a conventional 650W pump: maximum efficiency and

minimum energy consumption. |

| |

|

| |

|

|

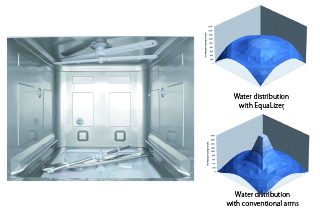

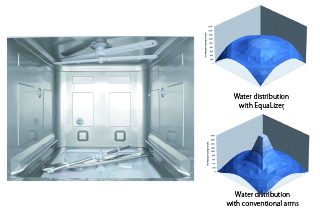

EquaLizer2 arms

The lower arm sprays water from the bottom up and the upper

arm from the top down. The use of identical arms imposes compromises

that tend to reduce performance. Colged adopts a steel lower spray

arm with high pressure nozzles and a composite material (acetal resin

with talc and fibreglass) upper arm with high power nozzles. Their

light weight offsets the difference in hydraulic power due to the longer

length of the circuit, facilitating rotation. Uniform distribution of the water

is guaranteed with also an improvement in cleaning power, for example,

on the back of soup plates.

|

| |

|

| |

|

| Innovation and ergonomics |

|

|

SmartClean construction

Save up to 40 minutes/day in end-of-cycle cleaning operations

as all points where food soil can accumulate have been eliminated.

Wash tanks without internal hoses, deep drawn rack guides,

deep drawn tank son front load and hood versions, ProStrain integral

light, shock-proof composite material tank filters and many other details

make our dishwashers the fastest to clean.

|

| |

|

| |

|

|

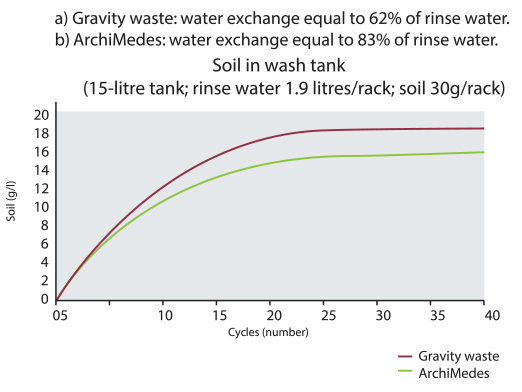

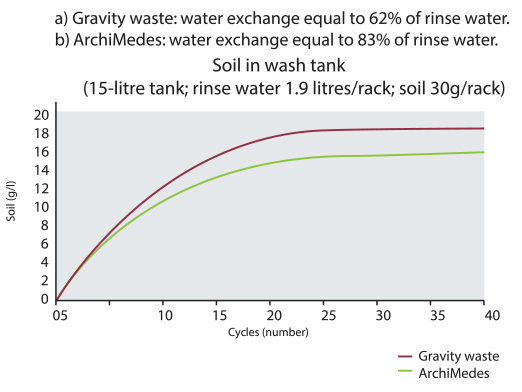

ArchiMedes drainage system

During rinsing, clean water is pumped into the tank to replace

the dirty water. With a conventional gravity waste, the clean water floats

on top of the heavier dirty water so that pumping in three litres, one

goes directly to the drain.

ArchiMedes, a Colged patent, exploits the principle of communicating

vessels with, therefore, a 67% to 85% increase in the amount of water

used to regenerate the detergent solution in the wash tank.

The water is also forced towards the bottom of the tank, also

discharging part of the built-up particles of dirt.

Wash water soils more slowly, water refresh is less frequent,

detergent concentration can be reduced by around 10%. The drain

pump is optional.

|

| |

|

|

|